Welding machines are essential tools in a wide range of industries, from construction and manufacturing to automotive repair and DIY home projects. Whether you’re using a 150 AMP Choked ARC Welding Machine, a 350 AMP Welding Machine, or a 600 AMP Welding Machine, these tools can experience wear and tear over time. If not properly maintained, they may face issues that can affect their performance, safety, and longevity.

This article aims to guide you on when to seek professional help for your welding machine repairs and how timely maintenance can save you money and extend the life of your equipment.

Understanding Welding Machines

Welding machines come in various types and capacities, each suited for different applications. Some common machines include:

- 150 AMP Choked ARC Welding Machine: Ideal for light tasks and hobby projects, this machine is popular among DIYers.

- 250 AMP Choked ARC Welding Machine: Suitable for medium-duty welding jobs, offering a balance between performance and affordability.

- 350 AMP Welding Machine: A heavy-duty machine that is used in industrial environments for welding thicker materials.

- 450 AMP Welding Machine: These are high-capacity machines designed for continuous industrial applications.

- 600 AMP Welding Machine: Known for their ability to handle large-scale projects, including structural welding.

Each machine comes with its specific features, including the type of welding (such as TIG, MIG, or ARC), which influences the type of maintenance and repair services it requires. Regular maintenance is key to ensuring the smooth operation of these machines.

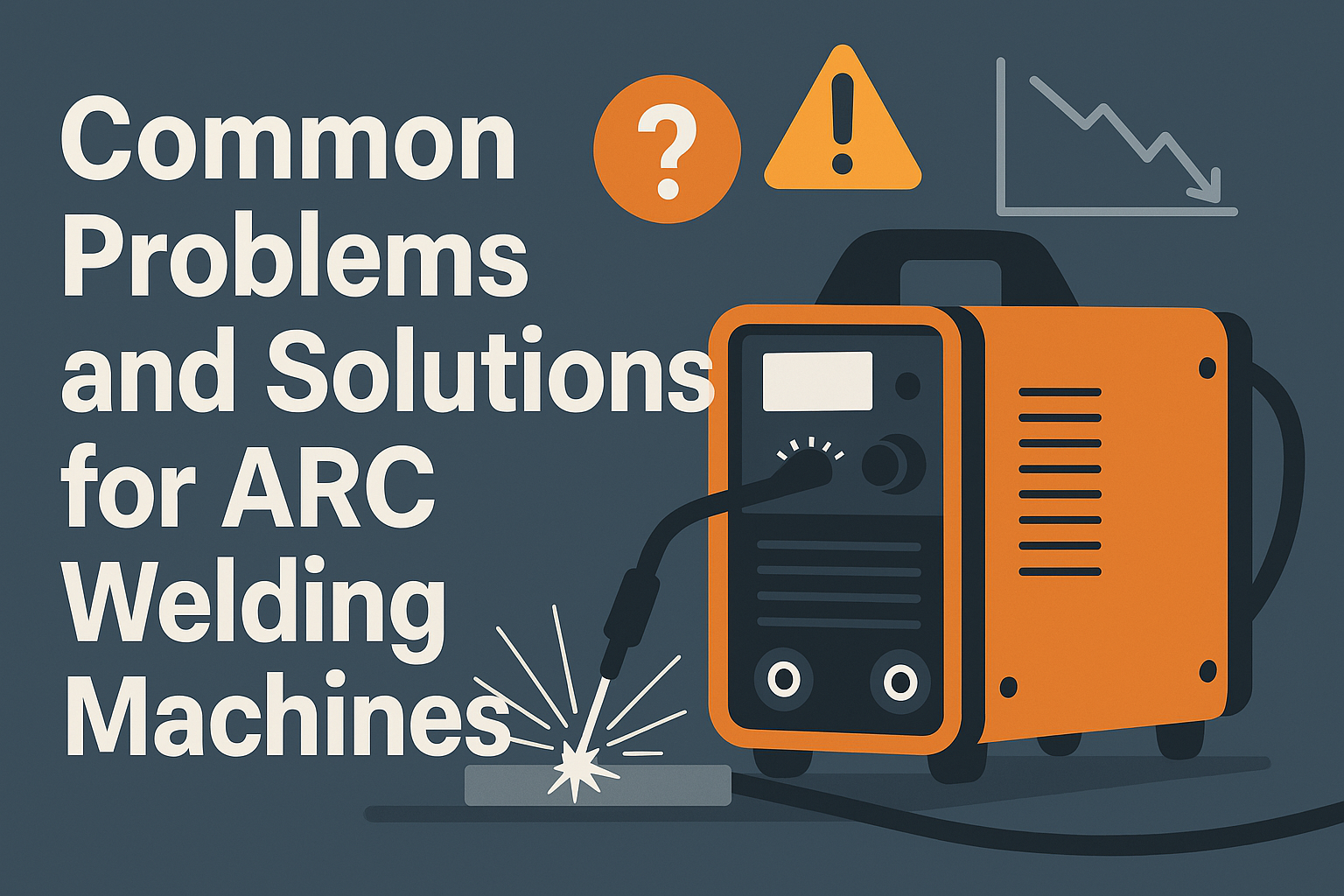

Common Welding Machine Problems and Their Solutions

Welding machines, no matter how advanced, can develop problems over time due to excessive use, poor maintenance, or environmental factors. Below are some of the most common issues faced by welding machines, along with when it’s time to seek professional help.

1. Inconsistent Arc Striking

Inconsistent arc striking is one of the most common issues experienced with ARC welding machines. This happens when the electrode fails to maintain a stable arc, resulting in an uneven weld.

Common Causes:

- Poor quality electrodes.

- Loose or worn-out welding cables.

- Incorrect amperage settings.

When to Seek Professional Help:

If you have already tried replacing the electrodes and adjusting the amperage settings, but the problem persists, it’s time to consult professional arc welding equipment repair services. Loose connections within the machine or internal faults in the power supply system may require a professional technician.

2. Overheating Issues

Overheating is common in machines such as the 350 AMP Welding Machine and 450 AMP Welding Machine, especially when they are pushed beyond their duty cycle. Overheating can lead to severe damage to internal components, including the cooling system and power electronics.

Common Causes:

- Overworking the machine beyond its rated duty cycle.

- Blocked or malfunctioning cooling systems.

- Lack of proper ventilation.

When to Seek Professional Help:

If your machine overheats despite regular cleaning and proper operation within the duty cycle, it might indicate an issue with the internal cooling system or power components. Seek arc welding machine repair services immediately to prevent further damage, especially for high-end machines like the 600 AMP Welding Machine or Double Holder 450 AMP ARC Welding Machine.

3. Poor Weld Quality

A significant drop in weld quality is often a sign of an underlying issue with the welding machine. Problems such as excessive spatter, porosity, or weak welds can compromise the structural integrity of your work.

Common Causes:

- Contaminated base material.

- Incorrect polarity settings.

- Incorrect electrode selection.

When to Seek Professional Help:

If the problem persists even after ensuring clean materials and correct settings, there may be an issue with the machine’s internal electrical components, such as the control board or transformer. An experienced repair technician can assess and resolve these issues.

4. Faulty Start Mechanism

Another common issue is the failure of the machine to start or a delay in arc ignition. This can be caused by damaged cables, connectors, or worn-out components.

Common Causes:

- Damaged or frayed cables.

- Worn-out electrode holders.

- Low power supply.

When to Seek Professional Help:

If replacing the cables and holders doesn’t resolve the issue, the internal circuitry or ignition components may be at fault. Professional welding machine repair services are essential for diagnosing and fixing these issues.

Why Professional Repair Services Are Essential

While minor repairs and maintenance tasks can often be handled by the user, professional welding machine repair services are necessary for several reasons:

1. Expert Diagnosis and Solutions

Professional technicians have the expertise to identify and resolve issues that may not be immediately apparent. For example, issues like short circuits, internal wiring problems, or malfunctioning control systems often require specialized knowledge.

2. Access to Quality Parts

Welding machines, especially high-capacity ones like the Double Holder 600 AMP ARC Welding Machine, require high-quality replacement parts. Professional repair services have access to authentic, manufacturer-approved parts, ensuring that your machine functions optimally after repairs.

3. Safety and Compliance

Welding machines involve high voltages and extreme temperatures. Attempting repairs without the proper training can lead to personal injury or further damage to the machine. Professional repair technicians are trained to handle these machines safely and comply with safety regulations.

4. Cost Efficiency

While it may seem tempting to attempt DIY repairs, incorrect repairs can lead to more significant issues and higher repair costs in the future. Professional repairs, on the other hand, address the root cause of the problem, saving you money in the long run.

When Should You Seek Professional Repair?

Knowing when to seek professional repair services for your welding machine can save you time, money, and stress. Here are some clear indicators that it’s time to call in a professional:

1. Frequent Overheating

If your welding machine, such as the 350 amp welding machine, frequently overheats despite ensuring proper ventilation, it could signal an issue with the internal cooling system or components that require professional attention.

2. Poor Performance Even After Replacements

If you’ve already replaced consumables like electrodes and cables and still experience problems like inconsistent arcs or poor weld quality, the issue might be deeper within the machine, requiring a technician’s expertise.

3. Electrical Issues

Electrical problems, such as irregular power supply, inconsistent voltage, or problems with the circuit board, are difficult to diagnose and repair without the necessary expertise.

4. Unusual Sounds or Smells

If your welding machine produces unusual sounds or smells (such as burning odors or buzzing noises), it is a clear indication that something is wrong inside. Do not attempt to use the machine in this condition, as it could pose safety risks.

5. Machine Fails to Start

A welding machine that doesn’t start or takes too long to ignite could have internal electrical issues. This is particularly concerning with heavy-duty machines like the 600 amp welding machine. Professional repair services are needed to ensure the machine is functioning properly.

Maintenance Tips to Avoid Frequent Repairs

Regular maintenance of your welding machine can prevent most of the issues discussed above. Here are some tips to ensure your machine stays in good working condition:

1. Regular Cleaning

Dust, debris, and welding spatter can accumulate in your machine over time. Clean your machine regularly, especially the cooling fans, electrode holders, and cables, to prevent blockages and overheating.

2. Inspect Consumables

Ensure that the welding cables, holders, and electrodes are in good condition. Replacing worn-out consumables will help maintain the machine’s performance and reduce the risk of failure.

3. Monitor Duty Cycle

Always operate your welding machine within its specified duty cycle. Overworking the machine can cause overheating and shorten its lifespan.

4. Keep the Machine Dry

Moisture can cause short circuits and rust inside the machine. Store your machine in a dry place and ensure that all components remain free of moisture.

5. Seek Professional Maintenance

Even with regular care, it’s essential to have your welding machine professionally serviced at regular intervals. This will help identify potential issues early and ensure that all components are functioning properly.

Conclusion

Welding machines are powerful and reliable tools when maintained correctly, but like all equipment, they require regular care to continue performing at their best. If you notice any issues such as inconsistent arcs, overheating, poor weld quality, or failure to start, it’s time to seek professional help. Deep Kalsi Electric Works offers comprehensive arc welding equipment repair services in Haryana and Mandi Dabwali, ensuring that your machine operates optimally.

Whether you’re using a 250 AMP ARC Welding Machine, 450 AMP Welding Machine, or a 600 AMP Welding Machine, professional repair services can save you time, money, and the hassle of dealing with serious machine failures. Don’t wait until it’s too late—schedule a repair today to keep your welding machines in top shape and avoid costly replacements.

For trusted and reliable welding machine repair, contact Deep Kalsi Electric Works. We are committed to delivering the best welding machine repair services in India.